There was a time, not too long ago, when Dell dominated the market for personal computers (PCs). It was a time that saw the company spawn a whole new industry of direct buying. Dell focused on a strategy that bypassed distribution channels by avoiding retailers and wholesalers altogether. This post looks at a Dell being a pull-push based supply chain example.

Instead of dealing with the added costs of distribution, Dell made the decision to sell directly to consumers. They then added to their value assertion by providing unmatched 24/7 technical support, shortened delivery times and unbeatable warranties.

The idea was to provide direct customer support, limit inventory levels and provide a relatively inexpensive customised finished good. By avoiding distribution and having a push/pull view of their supply chain, Dell was able to offer unmatched pricing to end-users for customised PCs.

It wasn’t long before other companies would try to copy Dell’s strategy. However, many companies soon learned that Dell’s approach combined a direct sales model with a push-pull procurement and supply chain strategy, one where Dell reduces its lead times on customised offerings by procuring exactly what’s needed to complete a customer’s order.

Dell’s Direct Sales and Supply Chain Strategy

In many ways, Dell’s process borrows from “Just in Time” (JIT) supply chains in terms of limiting inventory levels. However, Dell focuses more on a push-pull strategy, one where it pushes options to its customers and then uses that customer order to pull demand through Dell’s supply chain. At least, that’s how Dell started their process.

Nowadays, it seems as if Dell has somewhat abandoned that strategy altogether with respect to offering customised PCs as those options are no longer as vital as they once were. However, that doesn’t mean that Dell’s strategy is any less important in today’s marketplace. In fact, there are several companies that can run a variation of Dell’s approach.

An Example of a Push and Pull Supply Chain Strategy

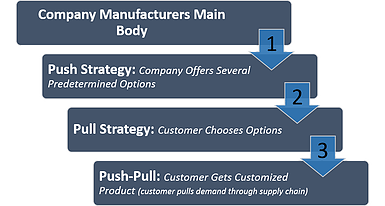

Instead of manufacturing the same product from a fixed materials list, a push-pull strategy combines a fixed materials list with a flexible materials list, one where the flexibility is tied into the options customers choose.

However, companies running a push-pull strategy don’t tend to let customers choose just any option. Instead, they control the options that are provided to customers so as to minimise lead times on delivery. In essence, the approach is to “push” customers to choose specific options. Once those options are chosen, the customer’s order “pulls” demand through the company’s supply chain.

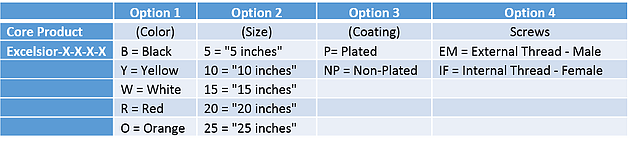

Another benefit of the strategy is that the nomenclature for the product being purchased is directly tied to the options chosen by a given customer. For instance, the first few numbers and or letters of the core product are fixed while the individual options that follow are not.

Here is an example of what the ordering process may look like for a company offering a customised finished good through a push-pull process.

The core product (Excelsior) stays fixed and is made from a fixed materials list. It’s the main body of the product and we can safely assume it is sitting on the shelf in the company’s warehouse. The end product is considered to be in a semi-finished state waiting for customers to place orders for their chosen options.

So, in this case, the Excelsior “body” is waiting to be finished with the customer-specific options. The list of options that follow (Option 1, 2, 3 and 4) allow the customer to choose a customised solution with minimal delivery times. For the sake of simplicity, we’ve kept the options fairly straightforward. However, it’s not uncommon for companies to have a long list of options.

Let’s assume a customer orders the Excelsior-B-25-P-IF product offering. This means they’ve ordered an Excelsior product that will be painted black, 25 inches long, plated, and have internal threads/female screws.

However, the company has all these options ready the moment the customer places the order because they have a demand history to call upon. In this case, the company has manufactured most of the finished good and is simply waiting for customers to place orders. When those customers order, they get the options they want and immediate delivery.

In order for the strategy to work, the company must manufacture or hold the core product on its shelf. Or, at the very least, it must have enough to quickly assemble the core product in order to maintain the time-critical delivery for the customer. In many ways, it’s as if the company pre-assembles a vast majority of the finished good and then waits for the customer to place their specific order.

Some businesses see the push and pull supply chain strategy as a combination of two distinct sales and/or marketing strategies. They may come to see the push strategy as relying upon multiple sales channels who push products to customers.

This might include selling through distribution or retail channels by offering those channels discounts, stocking deals and or rebates in order to incentivise sales. They then see the pull strategy as being separate and focused entirely on the end-user.

Dell’s strategy is unique in that it uses the savings accrued by avoiding distribution to offer unbeatable prices to the everyday consumer. It focuses directly on the end-user by bypassing those aforementioned sales channels and then passes on those savings with lower prices.

However, Dell also understands the benefit that those distribution sales channels provide in terms of technical support and warranties. So, it offers those same services to its end-user customers and at a much lower cost than what those distribution channels could offer.

In the end, Dell’s strategy was simple and straightforward. It combined a customer order strategy that drove its supply chain. The impetus was on driving customer demand and then using that customer demand to better manage procurement and, inventory control technology and overall inventory. It reduced pricing, secured high-volume business and helped to position Dell as a market leader.

Build Your Own Push-Pull Supply Chain Strategy Like Dell’s

If you want to learn more about the different supply chain consultancy services we offer, then please check out our page. Alternatively, if you want to speak to a consultant then get in touch today to discover how we can help you build a push and pull supply chain strategy like Dell’s.