Predictive Maintenance & its Impact on Supply Chains

Companies that operate with complex machinery, robotics and technology within their supply chains know that maintenance is a must-do. Continual efficient working of machines cannot

Companies that operate with complex machinery, robotics and technology within their supply chains know that maintenance is a must-do. Continual efficient working of machines cannot

Blockchain may be the buzz concept of 2018 but there’s good reason for that. Technology emerges when there is a driving need. That’s what has

The supply chain industry has been adopting machine learning and applying it to demand planning for quite some time now. We’ve seen its success and

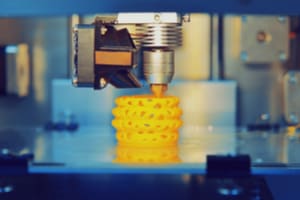

Additive manufacturing is a technological advancement in which computer-aided-design (CAD) software or 3D object scanners are used to create lighter and stronger parts. This technique

Logistics is increasingly under focus in modern businesses as it is an area where real differentiation can be made. Strategic input can create efficiencies which

3D printing is starting to make waves within manufacturing and production processes and it comes with its own preconceptions. We typically have in mind what we

Paul Trudgian Ltd | Supply Chain & Logistics Consultants

Arion Business Centre, 118 High St, Harriet House, Erdington, Birmingham B23 6BG | Registered in England & Wales 9283118